If you're a convert to "toothy" edges like we are then proper burr removal becomes the center of your world. We like toothy edges because they are easy and fast to create using, typically for us, a single grind process with a 80 - 180 grit ceramic belt on the Kally. The actual grinding process may take only 30 seconds to a minute. Now the work begins though, proper removal of the burr and removal of certain elements and artifacts of the burr can be a real challenge. The goal is to remove the burr completely without significantly reducing the tooth in the edge. We've been experimenting here with faster and surer methods of getting from A to B and the first order of business for us is to understand, as completely as possible, what the constituent components of burr formation are.

Burr formation does not appear to be some cataclysmic event. Formation of an easily recognizable burr seems to be a process. While there are those who seem capable of "seeing" a burr at its earliest formation stages we do not count ourselves among them without the aide of magnification. In practice, we have to rely on "feeling" the burr. What we have learned is that burr formation begins long before any of us can actually detect it tactilely.

We designed an experiment that builds on the work already established by our good friend Grepper. Grepper has shown us the enemy through his microscopic work many times in other threads. In our communications with Grepper we have non-affectionately named this enemy "LOW" or "line of weld". This is not because it is a "line of weld" but rather because it has the same appearance as a "line of weld". It is a booger indeed. Visible only via properly lighted microscopy, stout and firmly attached to the edge apex. Proper removal of this LOW will result in a 50 - 75 point improvement in BESS scores. Here's is a LOW image taken by Grepper with text added by us;

These layers are stuck together somewhat but not firmly bonded. When normal deburring methods are employed, more often than not, the top layers of burr are removed but leave the LOW intact and still stuck to the edge. The LOW has such a low profile that subsequent deburring attempts using common methods and materials are unable to pick it up and stand it up so that it can be removed. It can be picked up though and just to be prove it, Grepper performed this little trick and then took the photo. He used the point of an exacto knife to pry the burr up. We tried the same thing with the corner of a DE razor blade but it wasn't stiff enough to turn the LOW over. A single edge razor blade was and we were successful in standing the LOW up in the same fashion that Grepper had. Here's Grepper's picture with our remarks;

The LOW seems to be the first layer of burr laid down and it seems to be really well stuck to the side of the edge. It's also well attached to the edge apex. Subsequent grinding passes just seem to add to the volume of the burr. To support this theory we ran the following experiment. First we set the rest on our Kally at a fixed angle and then sharpened a knife and removed all the burr including the LOW. We did no leather refinement to the edge which seems to always be good for another 30 or 40 points but still the edge measured 150 and 155 and even though the belt we used was 80 grit.

Then we ground this already sharp edge again. But first we colored the edge black (grind side) with magic marker to make certain that the belt removed metal all the way to the edge. We made just one very light pass on just one side of the edge. There was no detectable burr present. Then we took a picture of the ground side.

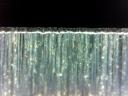

Not much to see other than the residual of the black marker buried in the grooves of the original grind marks. So we flipped it over for a picture of the opposite side of the edge;

And there we find a nicely formed LOW. Any subsequent and additional passes with the belt will add to the volume and height of this burr. As the burr is flipped back and forth during the grinding process it grows until it can be readily felt with a thumb. In the picture above, we couldn't feel it. If you strop the LOW on leather pad or belt it usually won't come off. If you persist and are finally able to remove it, a significant amount of tooth will be lost in the process. We are working with Grepper on ways to efficiently remove the LOW while preserving tooth and some methods do show a lot of promise. More on that later but in the meantime, we have identified the enemy. Grepper recently reported in an Exchange thread sub 100 BESS scores on a very average knife. In that case, proof that the enemy can be defeated.

Burr formation does not appear to be some cataclysmic event. Formation of an easily recognizable burr seems to be a process. While there are those who seem capable of "seeing" a burr at its earliest formation stages we do not count ourselves among them without the aide of magnification. In practice, we have to rely on "feeling" the burr. What we have learned is that burr formation begins long before any of us can actually detect it tactilely.

We designed an experiment that builds on the work already established by our good friend Grepper. Grepper has shown us the enemy through his microscopic work many times in other threads. In our communications with Grepper we have non-affectionately named this enemy "LOW" or "line of weld". This is not because it is a "line of weld" but rather because it has the same appearance as a "line of weld". It is a booger indeed. Visible only via properly lighted microscopy, stout and firmly attached to the edge apex. Proper removal of this LOW will result in a 50 - 75 point improvement in BESS scores. Here's is a LOW image taken by Grepper with text added by us;

These layers are stuck together somewhat but not firmly bonded. When normal deburring methods are employed, more often than not, the top layers of burr are removed but leave the LOW intact and still stuck to the edge. The LOW has such a low profile that subsequent deburring attempts using common methods and materials are unable to pick it up and stand it up so that it can be removed. It can be picked up though and just to be prove it, Grepper performed this little trick and then took the photo. He used the point of an exacto knife to pry the burr up. We tried the same thing with the corner of a DE razor blade but it wasn't stiff enough to turn the LOW over. A single edge razor blade was and we were successful in standing the LOW up in the same fashion that Grepper had. Here's Grepper's picture with our remarks;

The LOW seems to be the first layer of burr laid down and it seems to be really well stuck to the side of the edge. It's also well attached to the edge apex. Subsequent grinding passes just seem to add to the volume of the burr. To support this theory we ran the following experiment. First we set the rest on our Kally at a fixed angle and then sharpened a knife and removed all the burr including the LOW. We did no leather refinement to the edge which seems to always be good for another 30 or 40 points but still the edge measured 150 and 155 and even though the belt we used was 80 grit.

Then we ground this already sharp edge again. But first we colored the edge black (grind side) with magic marker to make certain that the belt removed metal all the way to the edge. We made just one very light pass on just one side of the edge. There was no detectable burr present. Then we took a picture of the ground side.

Not much to see other than the residual of the black marker buried in the grooves of the original grind marks. So we flipped it over for a picture of the opposite side of the edge;

And there we find a nicely formed LOW. Any subsequent and additional passes with the belt will add to the volume and height of this burr. As the burr is flipped back and forth during the grinding process it grows until it can be readily felt with a thumb. In the picture above, we couldn't feel it. If you strop the LOW on leather pad or belt it usually won't come off. If you persist and are finally able to remove it, a significant amount of tooth will be lost in the process. We are working with Grepper on ways to efficiently remove the LOW while preserving tooth and some methods do show a lot of promise. More on that later but in the meantime, we have identified the enemy. Grepper recently reported in an Exchange thread sub 100 BESS scores on a very average knife. In that case, proof that the enemy can be defeated.